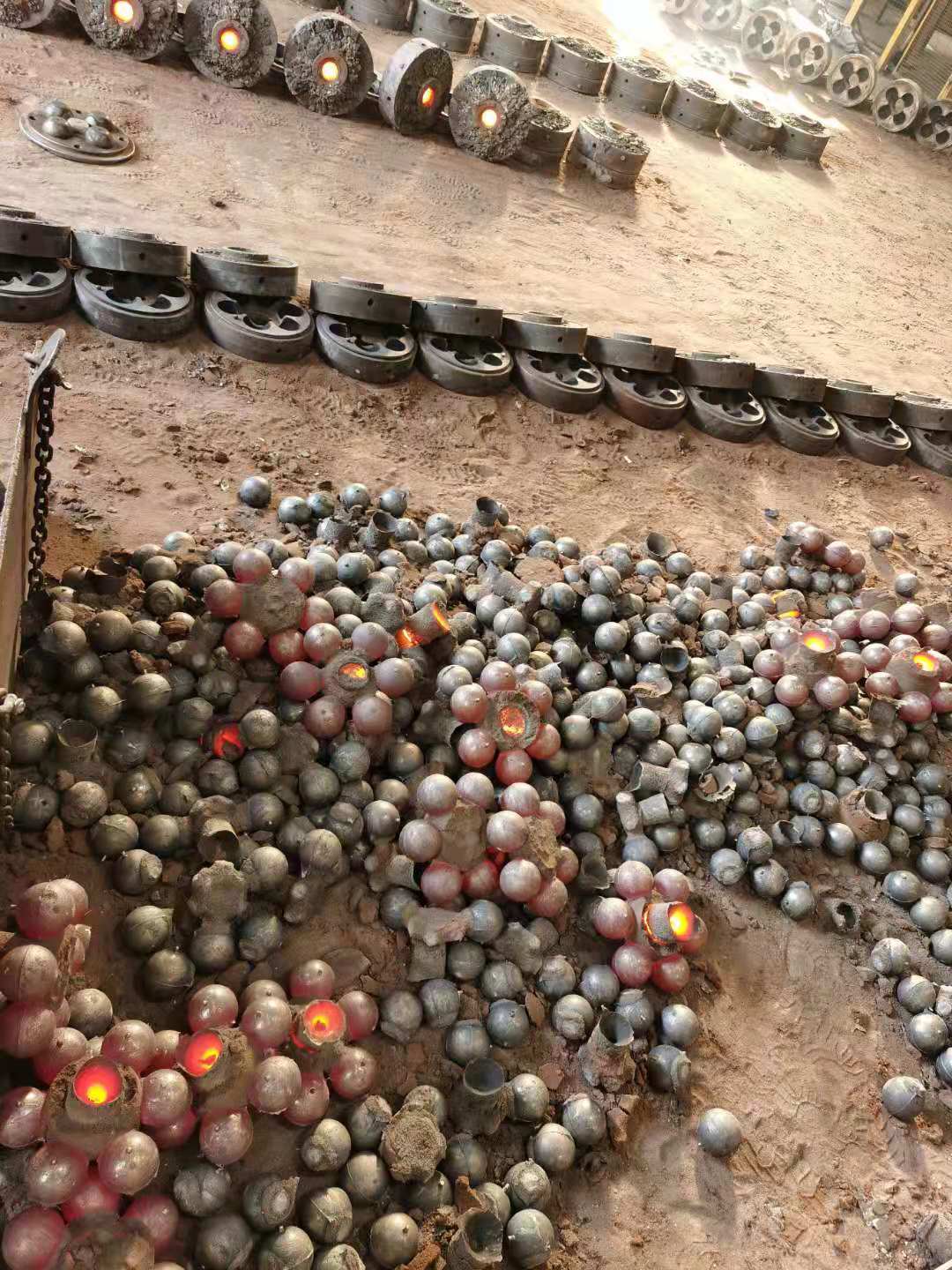

The loss of roundness and the loss of roundness of the grinding body do exist in the use of the grinding body (grinding media ball, grinding cylpebs). The loss of roundness of the grinding body reduces the grinding effect and reduces the output of the grinding machine, but due to the lack of specific statistical data, the National Standard GB / T17445-2009 and the building materials industry JC / T533-2004 have not been specified. The so-called out-of-round is the use of grinding body into polyhedron from the round, according to the normal law should be large ball grinding into the small ball (or large section grinding into small), the shape remains spherical (or cylindrical). The reason for the out-of-round is that the pieces on the surface of the ball (cylpebs) peel off or sag into polyhedral, apple-shaped or irregular shapes.(Dexin new materials)

(1) the grinding body production process is usually with pouring gates together, the gate is the final solidifying place, here the crystal time is long, the grain is coarse, the impurity gathers, this is the grinding body tissue or the weakest place, in particular, medium and low chromium ball without austenitizing heat treatment (from pearlite into martensite or Bainite), in the use of easier to concave, into apple-shaped ball.

(2) segregation of chemical composition and uneven heating or cooling in heat treatment are the causes of uneven surface hardness. Where the hardness is high, wear is slow, and where the hardness is low, wear is fast Especially the abrasive body with poor hardenability, the surface to center hardness difference is larger (hardness is not uniform inside and outside). Because of the uneven wear, the grinding body in the process of doing work is bound to uneven force, so the grinding body in the grinding process gradually formed polyhedron or IRREGULAR SHAPE.

(3) after heat treatment of High Chromium grinding media ball and cylpebs, there is still more austenite in the Matrix. The impact and temperature of the lapping body in the mill will lead to work hardening of the surface of the lapping body, volume expansion, and internal stress increase When the stress exceeds the yield strength of the Matrix, there will be massively spalling in the air-swept mill and coal mill. As time goes by, the grinding body will be out of round or deformed

(4) the use of the abrasive body is unreasonable and easy to cause the failure of the circle or deformation. Such factors as unreasonable grading specifications, too much or too little ball, too much grain size or poor abrasive, uneven supply and so on, therefore, it is necessary to use manufacturers according to the conditions of use and grinding indicators should be the strictly reasonable use of grinding body and add program.

(5) the foreign regulations on the out-of-round of the grinding ball are that the out-of-round part of the grinding ball accounts for more than 7% of the ball itself after 2,000 hours of use. The total amount of out-of-round of the ball and the percentage of the total amount of the ball used are the out-of-round rate. Missing”(maximum diameter-minimum diameter) / average diameter.

Our tunnel type heat treatment machine is widely welcome for quenching and tempering casting chrome grinding balls and cylpebs.

Betty 86 158 5636 2791

Star 86 18756355533 starwang577322@foxmail.com

Address: Heli Industrial Zone, Ningguo City, Xuancheng, Anhui Province, China.

molding line

metal mold

heat treatment furnace

grinding media

Ball Production Ancillary Facility

Wrench

Induction Furnace